As a leader in the specialty materials and surface technologies industries, we take pride in our commitment to supporting a multitude of diverse markets globally. From aerospace to medical, automotive to electronics, our versatility challenges traditional boundaries and our expertise in providing innovative solutions empowers industries with the transformative potential of advanced materials. At Kymera, we understand these innovative, high-quality products and services are the key to delivering outstanding customer value. As our passion for excellence converges with the unique demands of each of the markets we serve, we are driven to redefine the possible, setting new standards and propelling our purpose of shaping the future.

Aerospace & Defense

We are a world-leader in the production of high-quality master alloys, used as enhancing elements in the titanium industry, for use in the most demanding aerospace applications, including rotating disks for jet engines and integral airframe structures. We also supply the aluminum powder used as a key component in many of the master alloy variations.

We continue to add value throughout the life cycle of titanium products, boasting North America’s largest capacity for washing aerospace-grade turnings, sustainably supporting the infinite recyclability of the metal.

The breadth and diversity of Kymera’s materials has propelled our success as partners come to us for solutions tailored to support specific needs. Our additive manufacturing powders are ideal for use in these industries, supporting various applications. Our copper powder is also an excellent choice for applications such as friction pads for brakes as it is easily malleable, highly conductible, and resistant to corrosion. In addition to titanium, Kymera produces tantalum and niobium materials which provide significant benefit for increased hardness and strength, as well as improved heat resistance in electrical components and reliability under the extreme conditions in space.

Our materials aren’t the only solutions that shine in our portfolio. Our Surface Technologies group has engineered the HaloJetTM ID HVOF coating system to vastly improve traditionally limiting factors of corrosion and abrasion in landing gear components. HaloJetTM ID HVOF coating is the solution to improve inside diameter coating while eliminating hexavalent chromium from the production process.

Notably, on the defense side, Kymera is certified to apply a long-lasting, nonskid flight deck coating, co-developed with the Naval Research Laboratory, for use on aircraft carriers that carry the short take-off and vertical-landing (STOVL) F-35B fighter jets.

Automotive

Kymera materials have long paved the path in automotive performance, efficiency and design. Our materials are engineered for the unique challenges of the industry, driving toward the synergy between form and function. From lightweight and high-strength aluminum alloys improving fuel efficiency and providing metallic coating solutions, to our high-performance copper powders and brazing pastes enhancing the toughness and thermal conductivity of automotive PM parts, Kymera is uniquely positioned drive performance. From engine components to paints and coatings, to clutch and brake pads, Kymera has your metallic automotive needs covered.

Kymera is committed to sustainability in the transportation sector. While heavily supporting the production of the internal combustion engine, we are also progressing advancements in electric vehicle design, as well as alternative clean energy objectives including hydrogen generation. The goal is clear, if you reduce greenhouse gases, preservation of our planet and natural resources is possible.

Building, Construction & Infrastructure

Consumer

The consumer segment of our business is driven through particulate materials, including our aluminum powders, used in the production of cleaners, detergents and plastic wraps. Our bronze bearings are also critical in household small appliance motors to improve functionality and decrease noise.

Kymera is a technology leader in the water filtration market with our KDFTM high-purity copper-zinc media targeted for reducing heavy metals, microorganisms, and scale, lowering total costs and decreasing maintenance of point-of-use and point-of-entry household water systems. KDF process media are used for a variety of pretreatment, primary water treatment and industrial treatment processes. They are generally used in place of, or in conjunction with, granular activated carbon filters, even carbon block or inline filters. KDF water filter media extend the life of systems while protecting the carbon bed against fouling by bacteria growth.

Electronics / Semiconductors

Kymera is actively developing materials for use in the electronics and semiconductor industries. Our tantalum and niobium metals support improved heat resistance and reliability in electrical components, and we are using that experience to design new solutions for surface coatings for semiconductors. The plasma thermal spray coating process is highly effective for semiconductor components. In addition, our SIL-Shield silver coated powders are present in the composition of printed electronics.

Energy

In addition to oil and gas, Kymera is committed to supporting advancements in renewable energy and battery storage, supplying our titanium and titanium alloys into these applications.

Industrial

A key example of how Kymera is benefitting agricultural technology is through the application of BrazeCoatR on spreading vanes for fertilizer spreaders. Our superior coating not only provides cost efficiencies through much longer service life, but also provides high impact resistance, increased corrosion resistance, a decreased tendency for the fertilizer to stick due to a smoother surface and allows for constant spreading properties even with long throwing distances.

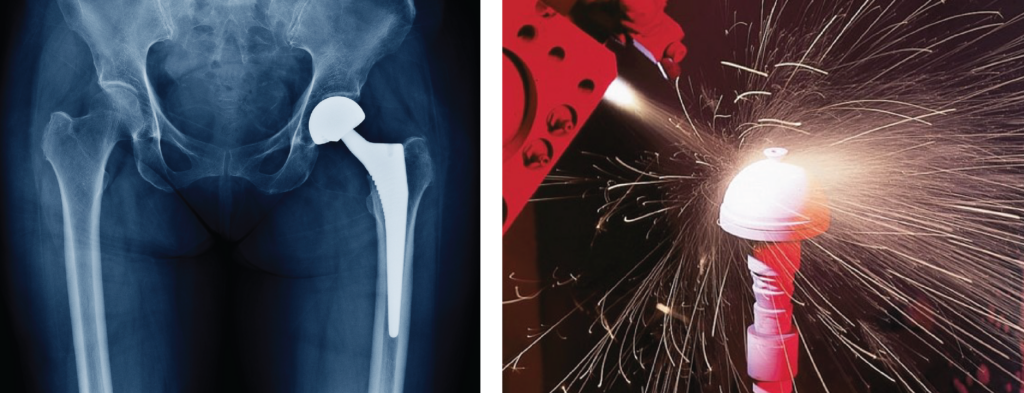

Medical

Medical companies across the globe trust Kymera to provide the highest quality titanium powders for various medical applications, including coating powders for orthopedic implants. Our powders provide enhanced osseointegration with custom titanium morphologies, specialized by hydride-dehydride processing. We also supply tantalum powder heavily utilized in medical applications as well.

Let’s Get Started

Want to learn more about our products and services? Get in touch with us for more information today.

Learn More