Service Form

Weld OverlayMarkets

EnergyIndustrialApplications

PipelinesPiping System FabricationSevere Service ValvesSlurry Transportation

Back

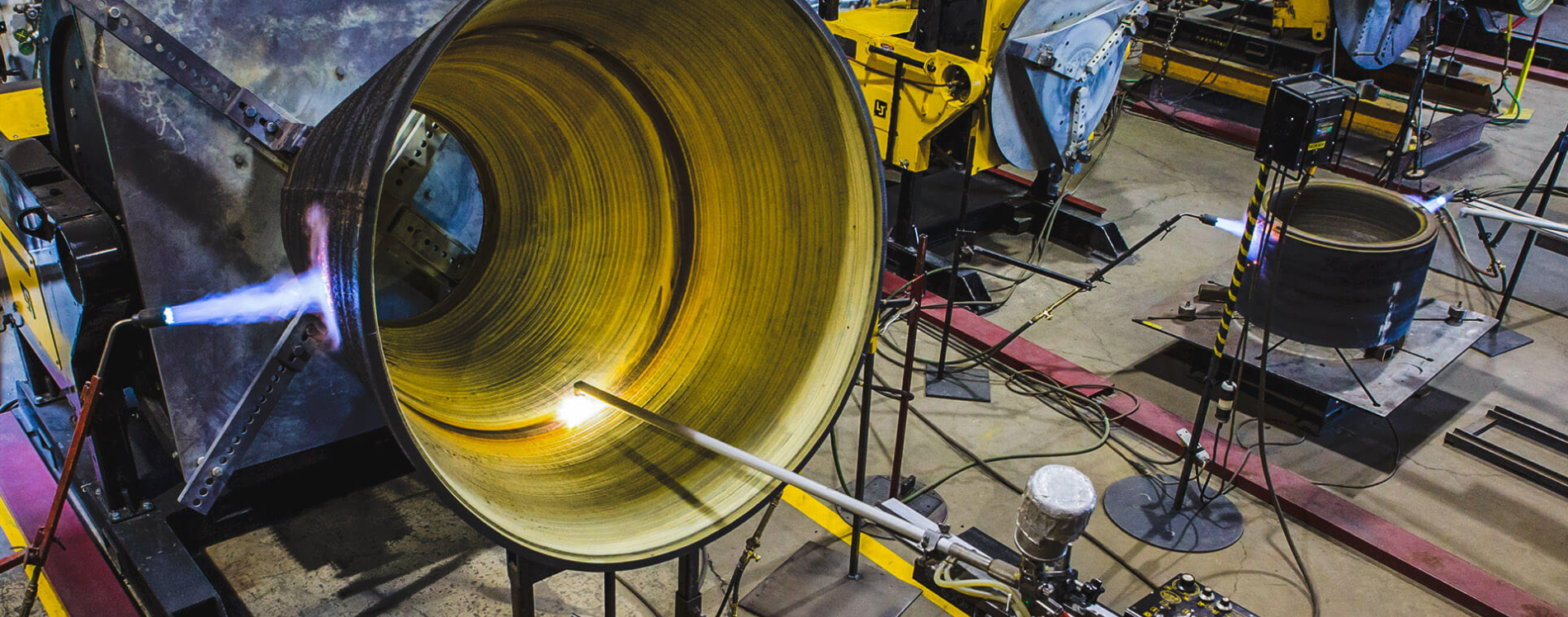

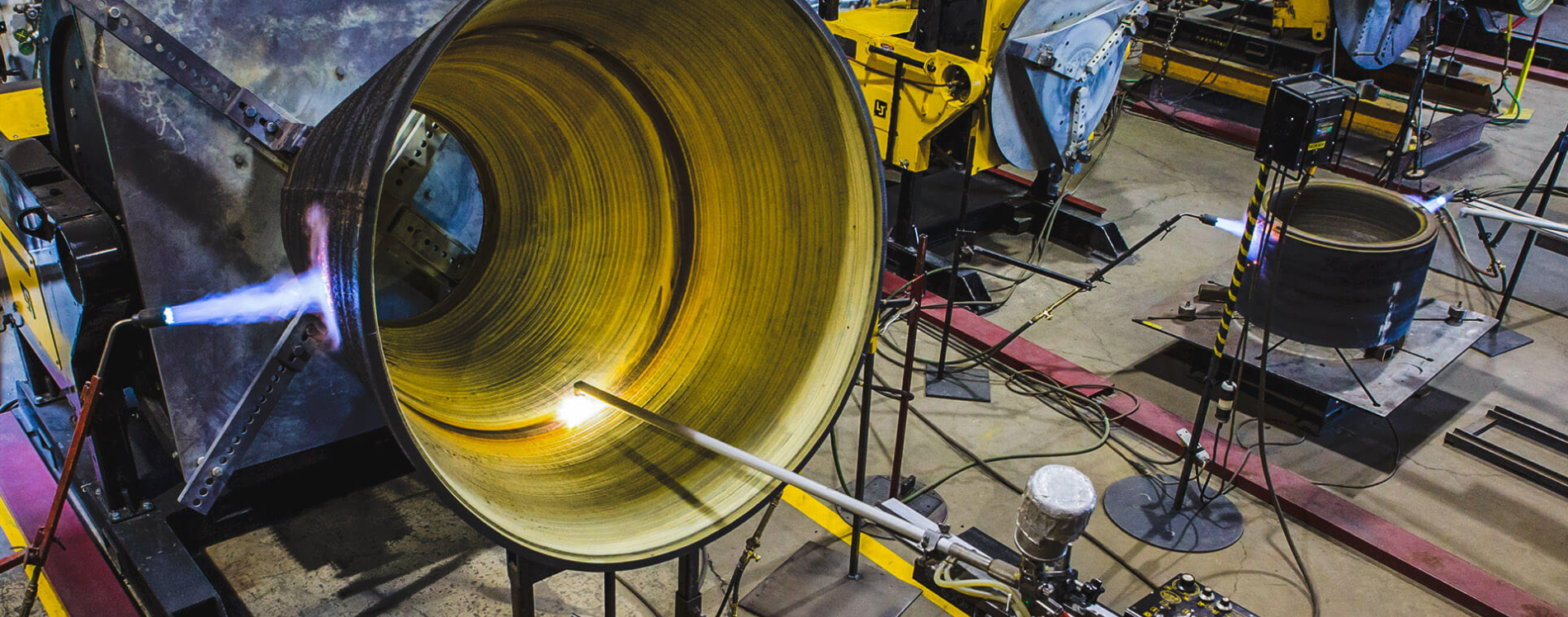

Spray and Fuse Tungsten Carbide

Description

Spray and fuse is a continuous brazing process that applies the coating and fuses it to the base material in a single process. This process does not melt the base material and consequently there is no dilution of the overlay alloy. The bond is created by the diffusion of atoms between the overlay alloy and base material resulting in a very dense, hard coating with high bond strength.

Features & Benefits

Low heat input reduces dissolution of WC/WC2 during application

- Allows the use of harder WC/WC2 carbides which provide better wear resistance than mono crystalline WC carbides

- Provides better wear life in high impact conditions

Low heat input results in a cooler weld puddle with less carbide sinking

- More even carbide distribution extends service life

Low heat input results in no dissolution of the base material

- No formation of brittle intermetallic phases greatly reduces cracking

Deposit rates up to 15lbs/hour (6.8kg/hour) and up to 0.25” (6mm) per pass

- Economical application of thick overlays

Low residual stress in the overlay allows for multiple passes without cracking and spalling

- Capable of applying thick overlays, up to 1” (25mm) for maximum service life

Low residual stress makes the overlay very impact resistant

- Spray and fuse overlays are excellent in high impact applications such as Tee spools

ASME recognized welding process

- Overlays can be applied to registered pressure equipment and piping

Let’s Get Started

Want to learn more about our products and services? Get in touch with us for more information today.

Learn More