Metal Types

CobaltNickelProduct Form

AlloyTapeMarkets

Aerospace & DefenseEnergyIndustrialApplications

Repair BrazingInnoTape

Description

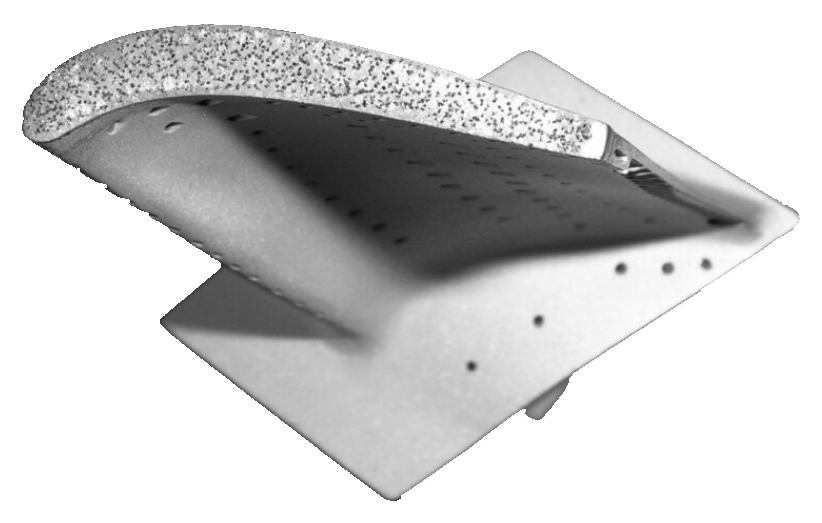

InnoTape is a polymer bonded, flexible tape consisting of Nickel or Cobalt based super-alloy and brazing filler metal powders, which are used for repair and restoration of gas turbine components through the diffusion brazing process.

These flexible repair tapes can be cut easily to the desired geometry and placed onto the repair parts including curved surfaces with specially developed adhesives, resulting in a contour-accurate new surface with properties similar to the base material after brazing.

Pre-sintered preforms (PSPs) derived from InnoTapes are powder metallurgically produced binder free sheets of desired composition. PSPs are manufactured in near-net shape in the required geometries and fixed to the repair parts by means of tack welding. Flawless joints with the least amount of porosity and almost no shrinkage are produced after brazing of such PSPs.

Three-dimensional preforms offer exact adjustment for complex shaped repair areas of turbine parts reducing expensive manual reworking after brazing, which are tailored individually and precisely according to the customer-specific requirements.

- InnoTapes are available as single, double, triple or multilayer flexible tapes or PSPs of the desired composition consisting of Ni/Co-based superalloy (like, Mar M 247, Mar M 509, Rene 80, X-40, Inco 718, T-800, etc.) and Ni/Co-based standard brazing filler metals or activated diffusion braze alloy powders.

- Get the benefits from the services Kymera provides: From the definition and development of customer-specific solutions to the delivery of tapes and preforms, including consultation and training in the handling of InnoTape.

Applications: Industrial Gas Turbine (IGT) & Aviation Gas Turbine (AGT)

Gas turbine blades and vanes are subject to a combination of high temperature, high mechanical load and oxidation conditions during operation, causing various types of degradation. The subsequent wear of the surfaces results initially in a reduction of the efficiency and ultimately in the failure of the turbine. The original geometry and mechanical properties of the components can be restored by repairing the turbine blade through a brazing process, which significantly reduces the expense of replacing the turbine components.

Let’s Get Started

Want to learn more about our products and services? Get in touch with us for more information today.

Learn More