Metal Types

CopperProduct Form

PastePowderMarkets

AutomotiveBuilding, Construction & InfrastructureConsumerIndustrialApplications

Powder MetallurgyStructural ComponentsInfiltrant Powders

Description

Infiltrating powders (IPs) are typically copper-based materials blended or alloyed with other metals. They are supplied in a press-ready form so customers can compact the material into slugs or rings.

IPs are designed to be used in a one-step heating cycle during which the green ferrous matrix is simultaneously sintered and infiltrated. IPs are processed to minimize normal erosion (dissolving of the iron matrix during infiltration) and as a low-, medium-, or high-efficiency infiltrant powder.

IPs fill the pores/voids of a sintered PM compact using a metal or metal alloy of a lower melting point than the base material. The infiltration process will produce parts with higher density, increased strength, toughness, hardness, improved impact strength, and thermal conductivity compared to the base metal part.

Infiltrated parts can be easily plated, welded, or brazed and will have improved machinability. Infiltrated steel parts will respond to standard heat treatment practices.

Characteristics

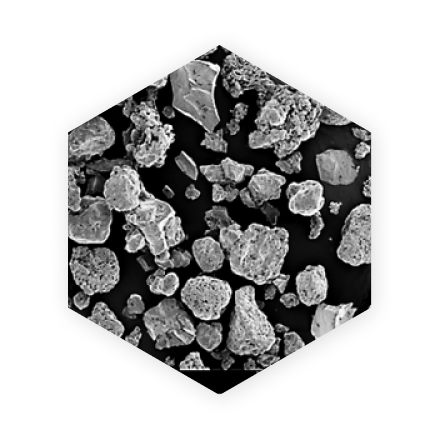

- Powder:

Typically > 93% copper

Particle size -100 mesh (<150 µm)

Typical apparent density 3.0 g/cm³

Pre-lubricated, press-ready powders with excellent green strength

Grades are tailored to provide high efficiency, low adhesion and residue, and minimal erosion - Paste:

No tooling is required for PM compacts

Eliminates pressing and handling of fragile PM compacts

Ease of automation

Reduced dusting

Precise weight control

Improved control of part density

Let’s Get Started

Want to learn more about our products and services? Get in touch with us for more information today.

Learn More