Metal Types

High-Performance Coatings & PastesProduct Form

PasteMarkets

Aerospace & DefenseAutomotiveBuilding, Construction & InfrastructureEnergyIndustrialMedicalApplications

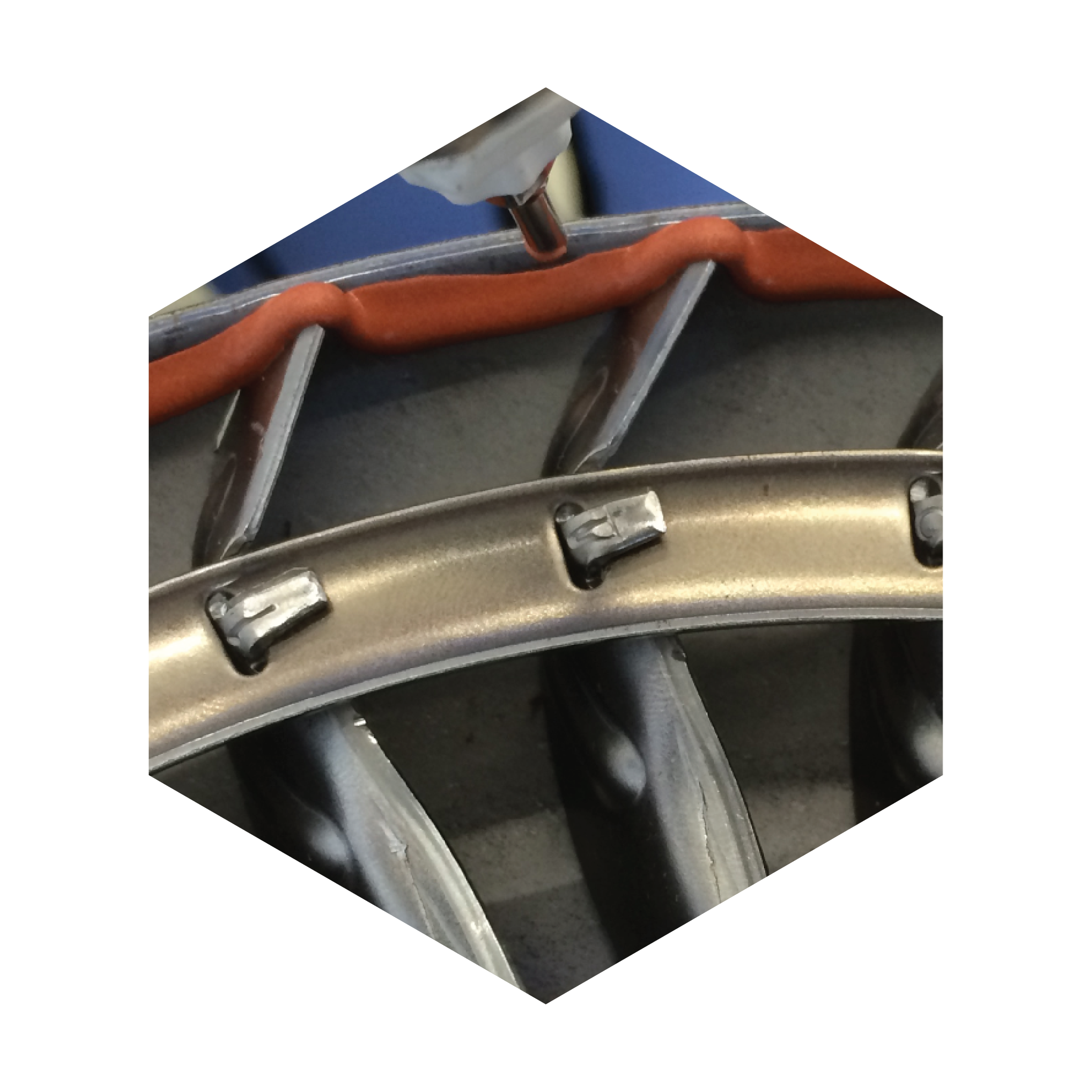

BrazingMetal JoiningInnobraze Brazing Paste

Description

Innobraze Brazing Pastes are designed for furnace brazing of mild steel, carbon steel, stainless steel, or cemented carbides under a protective atmosphere or in a vacuum. Steel parts may be hardened after brazing.

The copper filler metals, such as high-purity copper, copper-tin, copper-manganese, copper-nickel, or copper-iron for wide gap brazing, are the ideal solution when joints of high strength and ductility are required.

Silver filler metals are suitable for joining dissimilar materials. They can be processed at low brazing temperatures.

The nickel- and iron-based filler metals have very good oxidation resistance at elevated temperatures up to the melting range and allow application at high service temperatures. Due to its high resistance against corrosion, these filler metals are frequently used for applications in aggressive environments.

Specialty filler metals are tailored to meet the customer’s requirements.

Examples include active brazing pastes for the brazing of ceramics and diamonds, diffusion brazing filler metals, Reactive Air Brazing (RAB) pastes, pastes for the brazing of sintered parts, etc.

Characteristics

- Innobraze Brazing Pastes are available in grades that include various filler metals such as copper-, nickel-, iron- or silver-based

- All Innobraze Brazing Pastes are flux-free, have a high metal content, and have excellent storage properties

- Brazing Pastes are suitable for manual or automated dispensing. The pastes can be adjusted for screen printing or spray applications

Special Alloys

Copper Alloys

Nickel Alloys

Let’s Get Started

Want to learn more about our products and services? Get in touch with us for more information today.

Learn More