Metal Types

AluminumProduct Form

Extruded BarExtruded WireMarkets

Aerospace & DefenseAutomotiveBuilding, Construction & InfrastructureIndustrialApplications

Structural ComponentsAluminum Extrusions

Description

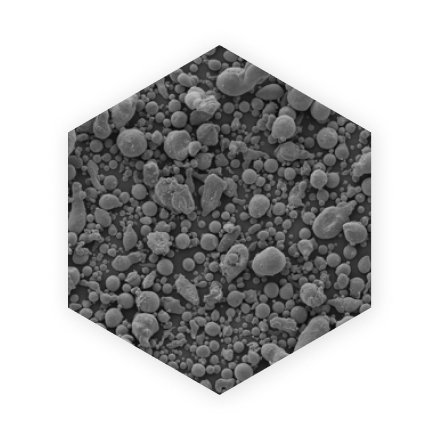

Aluminum alloy powders for hot extrusion are produced using air or inert gas atomization. Powder extrusion provides a means of consolidating materials that are difficult or impossible to process by other manufacturing means.

Hot extrusion can produce microstructural refinement and minimize segregation to improve material properties and performance.

Standard and custom alloys can be produced.

Characteristics

- Particle morphology can be tailored to application by selection of atomization gas

- Wide range of alloy compositions available, including custom alloys

- Custom particle size ranges available

Let’s Get Started

Want to learn more about our products and services? Get in touch with us for more information today.

Learn More